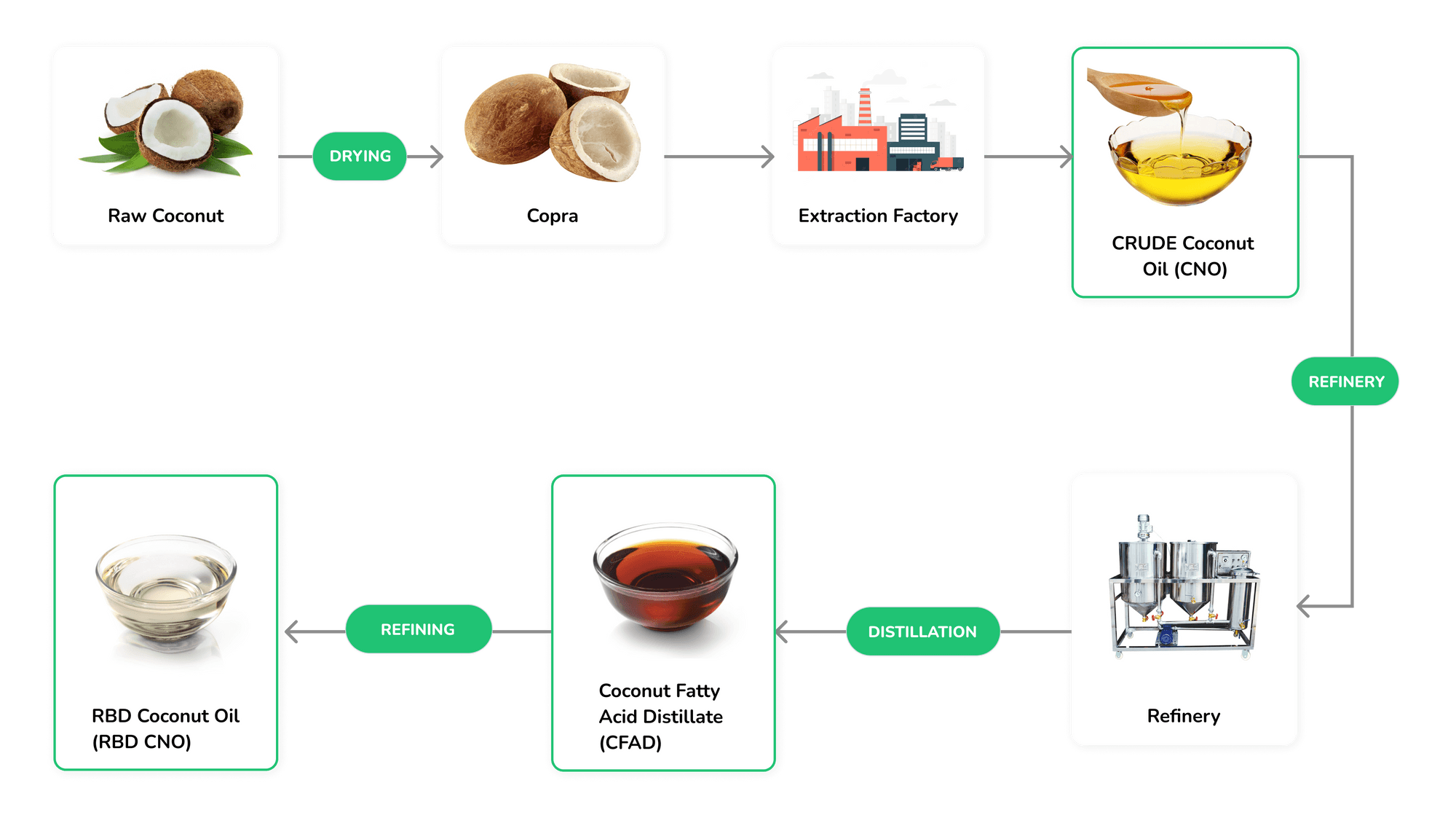

How production proccess of refined coconut oil (RBD Coconut Oil)

Refined coconut oil (RBD Coconut Oil)

On the other hand, refined coconut oil undergoes some additional processing to make it better suited for cooking.

The process begins with pressing crude coconut oil from copra. At this step, the process may be similar to the dry extraction of unrefined coconut oil. Next, one or more of the following steps may occur, depending on the manufacturing process.

- Degumming. The crude coconut oil is mixed with a degumming agent to remove gums, which can change the texture and quality of the oil. The oil is washed in water to separate these gums from the oil.

- Neutralizing. Sodium hydroxide, or lye, is added to the oil and forms a soap with free fatty acids in the oil. The oil is then washed with water, removing the soap and free fatty acids. This reduces the risk of rancidity, as free fatty acids are prone to oxidation.

- Bleaching. The oil is “bleached” by filtering it through an activated clay filter. No bleach is used in this process.

- Deodorizing. The oil is heat-deodorized to remove any remaining coconut scent or taste.

While the resulting coconut oil is more highly processed, it has a higher smoke point of 400–450°F (204–232°C), which makes it more suitable for high temperature cooking. For the most part, it’s also flavorless and odorless.

Additionally, refined and unrefined coconut oils have similar nutrient profiles, providing 120 calories of pure fat per tablespoon (14 grams). The two types contain similar ratios of MCTs, lauric acid, and saturated and unsaturated fats.